The product conforms to IEC 61000, GB/T 3859 and other standards, and has been certified by CE, EAC, CCC and other authorities. It has such functions as voltage stabilization, current limiting, soft start, over-voltage and over-current/over-temperature protection, automatic fault restart, etc. Optional photoelectric matrix vehicle identification system, encoder position tracking module, remote HMI operation station and non-sparking transition device, fully compatible with stepping, intermittent and continuous pass electrophoresis process.

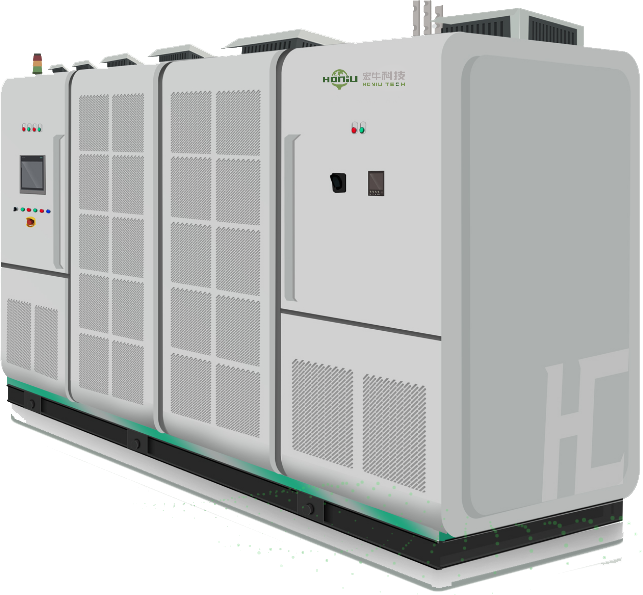

Our products include silicon controlled series power supply, IGBT series power supply and silicon carbide (SiC) series power supply. The distributed modular power supply is the mainstream solution in the industry.

Widely used in passenger vehicles, commercial vehicles, agricultural machinery, household appliances, aviation, ships, medical devices, military equipment and other fields.

| Model | Parameter |

|---|---|

| Input voltage class | 3Φ /480V/550V/620V/10KV/35KV Various voltage levels |

| Output voltage range | 0-400V/0-500V (Continuously adjustable) |

| Output current range | Single module power supply: DC35A/50A/100A/200A Silicon controlled power supply: SDC20000A customizable |

| Power supply efficiency | ≥96.5% (Silicon carbide power supply, full-load working condition) |

| Power factor | ≥0.95 (Full load range) |

| Protection class | IP54 (Dust and water proof) |

| Heat dissipation mode | Pure air cooling |

| Control accuracy | Voltage ± 0.5%, current ± 1% |