Electrophoresis coating

Hydrogen production by water electrolysis

Electric flocculation and water treatment

Vacuum coating film

Heating of semiconductor

Electroplating

Electrolytic metal metal

Electrolytic gas

Smelting of rare earth

Ionic membrane caustic soda

Graphite heating

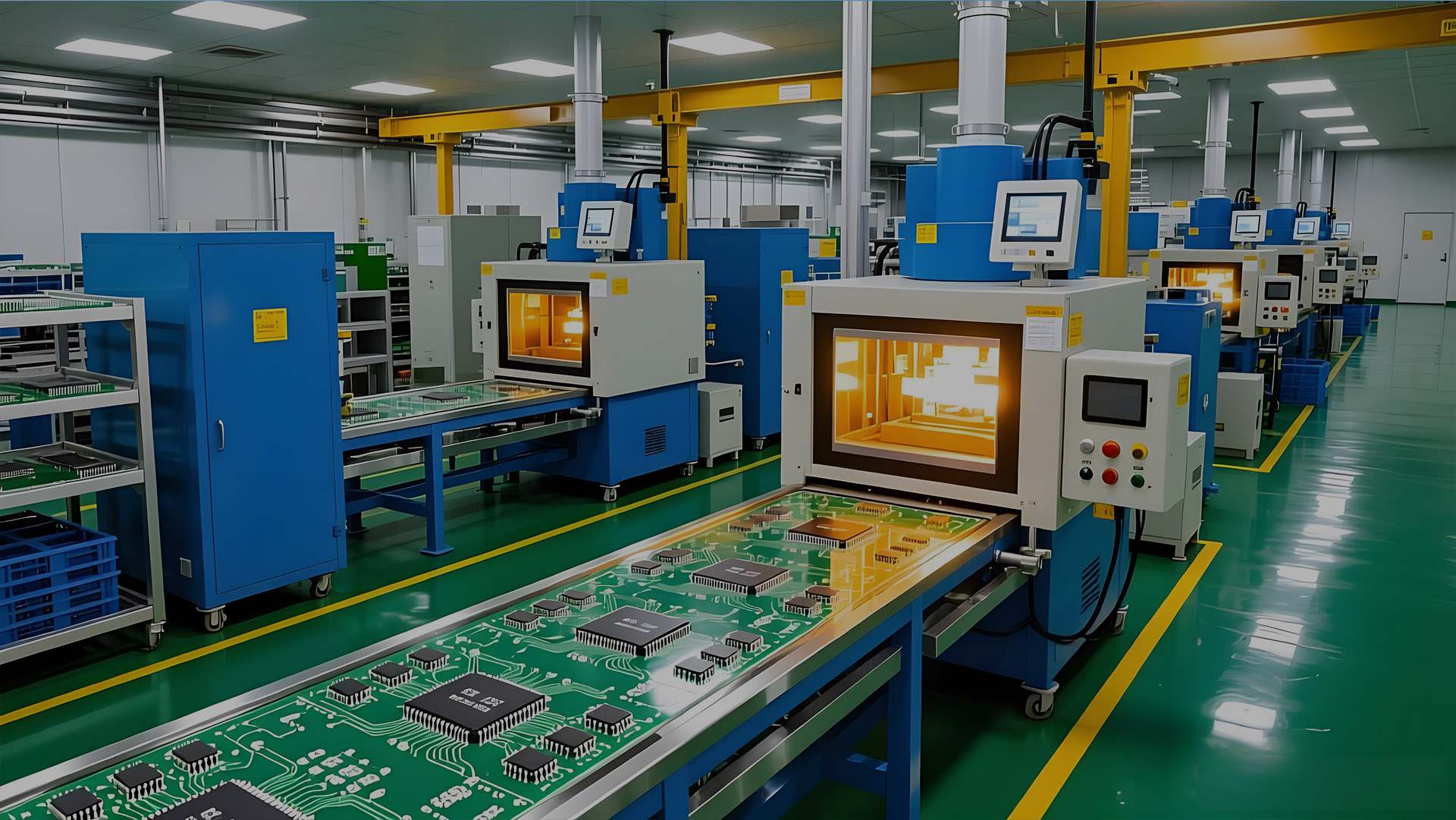

PCB(Printed circuit board)

Electrophoresis coating

Single machine up to 100 MW, 30% energy saving

Application Scenarios

Product Display

Product Information Download

Hydrogen production by water electrolysis

A single unit can reach 100 megawatts, saving 30% in energy.

Application Scenarios

Product Display

Product Information Download

Electric flocculation and water treatment

Single machine up to 100 MW, 30% energy saving

Application Scenarios

Product Display

Product Information Download

Vacuum coating film

Single machine up to 100 MW, 30% energy saving

Application Scenarios

Product Information Download

Heating of semiconductor

Single machine up to 100 MW, 30% energy saving

Application Scenarios

Product Display

Product Information Download

Electroplating

Single machine up to 100 MW, 30% energy saving

Application Scenarios

Product Display

Product Information Download

Electrolytic metal metal

Single machine up to 100 MW, 30% energy saving

Application Scenarios

Product Display

Product Information Download

Electrolytic gas

Single machine up to 100 MW, 30% energy saving

Application Scenarios

Product Display

Product Information Download

Smelting of rare earth

Single machine up to 100 MW, 30% energy saving

Application Scenarios

Product Display

Product Information Download

Ionic membrane caustic soda

Single machine up to 100 MW, 30% energy saving

Application Scenarios

Product Information Download

Graphite heating

Single machine up to 100 MW, 30% energy saving

Application Scenarios

Product Information Download

PCB(Printed circuit board)

Single machine up to 100 MW, 30% energy saving

Application Scenarios

Product Information Download

I Couldn't Find A Suitable Solution?

Get Free Consultation >

Simplified Chinese

Simplified Chinese