On July 2-3, 2018, Car Body Painting 2018, the 6th Car Body Painting Engineering Development Forum was successfully completed in Shanghai Jumeiya Himalaya Hotel. Baoding Hongcheng Converters, as one of the sponsors of the forum, attended the conference and made a speech on the application of HC-MACS (IGBT modular power supply), a new solution for electrophoretic painting energy conservation.

The conference focuses on intelligent green coating plants, new material spraying solutions, painting workshop energy conservation and consumption reduction, digital factory planning and other new body coating processes, new equipment, new technologies and opportunities and challenges, attracting the conference through speech reports, summit discussions, exhibits and other forms to provide suppliers and technical experts with a platform based on technical exchanges and centered on business match-making

The forum attracted more than 300 engineering and technical personnel from many original equipment suppliers and host manufacturers. A total of 17 keynote speeches were held and 17 guest speakers actively shared their years of practical experience and new technical knowledge of the industry. During the meeting, 2 guest discussions were held, and several industry personnel discussed on "the road of intelligent manufacturing of future automobile painting" and "energy saving lean countermeasures of automobile painting workshop".

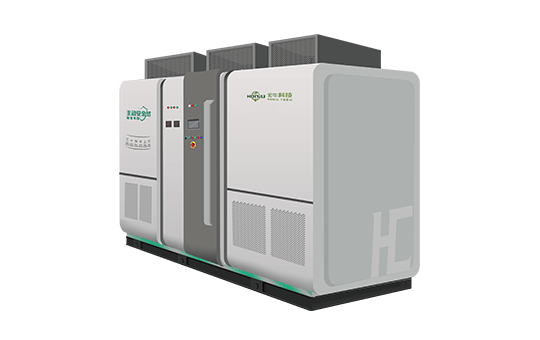

The speech at this forum of Baoding Hongcheng Converters focuses on the new energy-saving solution for electrophoretic painting -- HC-MACS (IGBT module power supply) application. MACS (IGBT module power supply) application technology Each IGBT module corresponds to the power supply mode of one anode tube. The system automatically tracks the position of the vehicle body. With a single anode tube as a small unit, the voltage and current of multiple areas of the vehicle body can be adjusted to achieve the effect of uniform paint film. MACS (IGBT module power supply) has the following application characteristics:

1. Equipment failure does not affect production

2. Electrophoresis film thickness is more uniform and can be controlled within 1-3u

3. Increase model, increase production and reduce capacity expansion cost

4. Electrophoresis area of 100 square meters can save 0.5Kg paint

5. M2 electrophoresis area can save 1 degree of electricity

6. Anode tube current limiting protection and digital monitoring, service life extended 3-5 years

7. Power factor up to 0.96-1, saving reactive compensation device

8. Low operation noise.

Hongcheng converter applies IGBT switch power supply new technology to coating cathode electrophoresis, and solves technical difficulties in high-power switch power supply within 5 years.

The forum is full of lively atmosphere and lots of field interactions. It is very inspirational for equipment integrators to discuss new equipment and technologies together with main engine plants. At the same time, it also covers the cutting-edge intelligent and automatic equipment topics that we are very concerned about, and the discussion on lightweight is also very deep, which is a very good learning opportunity for us. We will continue to adhere to the service concept of "providing customers with trusted products", work hand in hand with customers with a cordial attitude, constantly break through the technical field and improve product quality to create a Chinese electrophoretic power supply brand!